Search

Providing different sizes and shapes for your customized products, ranging from circular bars and tubes to square bars and tubes, and many more

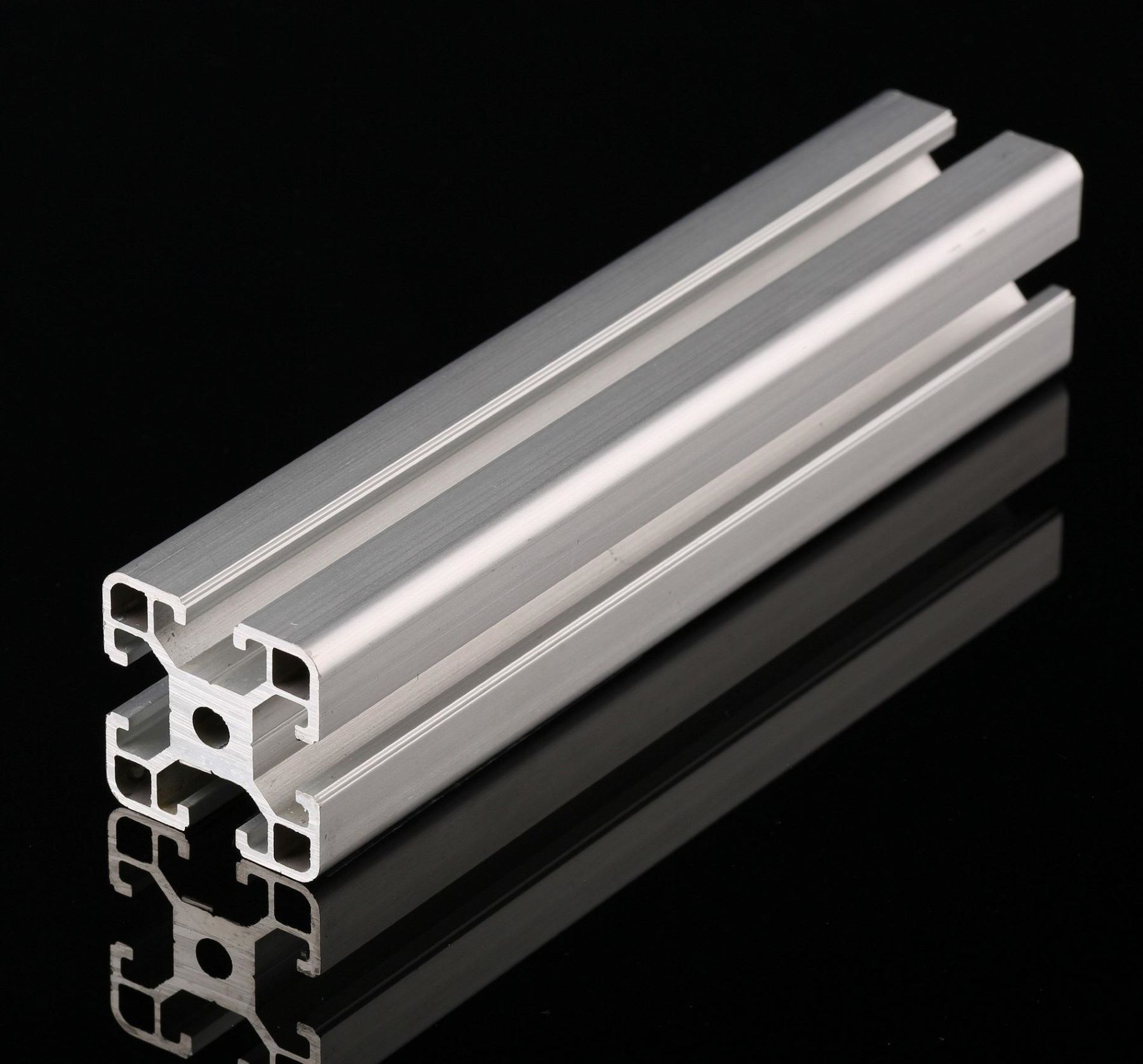

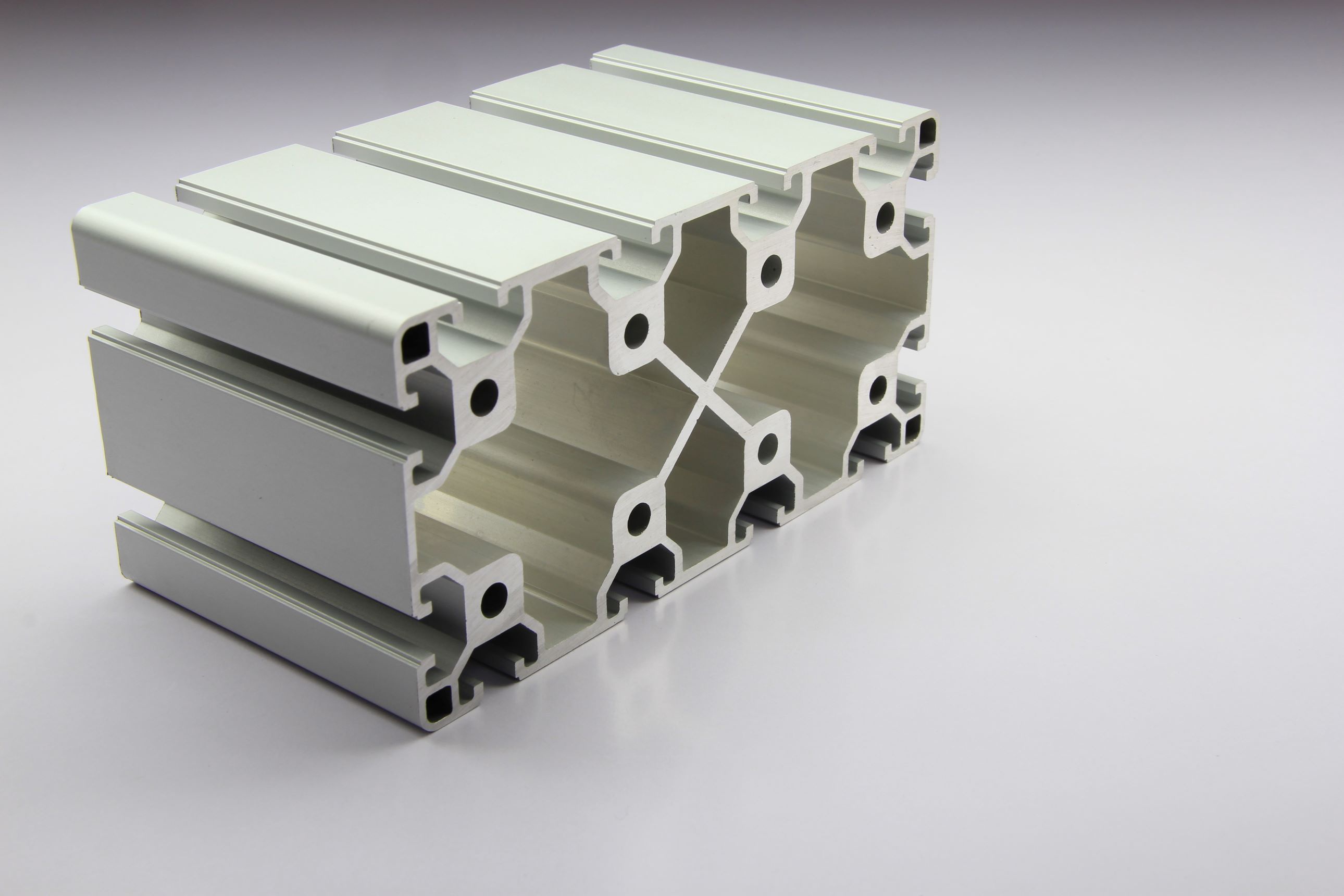

Aluminum Extrusion

Aluminum extrusion is a machining process in which aluminum alloy material is heated at high temperature and then forced out to form a specific cross-sectional shape by applying pressure through a die. It is capable of producing a variety of complex aluminum profiles. Through this process, aluminum profiles not only have a lighter weight and higher strength, but also can be customized in size, shape and surface treatment to meet different design and functional requirements.

Welcome to our world of aluminum extrusion products! We not only provide standard profiles, but also customize them to meet the special needs of different industries.

Advantages of Aluminum Extrusion

Aluminum extrusion technology has become one of the indispensable materials in various industries thanks to its high strength, light weight, corrosion resistance, customizability and environmental friendliness. Whether in the fields of construction, transportation, electronic equipment or industrial manufacturing, aluminum extrusion profiles have shown unique advantages and a wide range of application prospects.

High strength and lightweight characteristics: Aluminum extrusion profiles are strong and lightweight, making them more economical and convenient for transportation, installation and use. Especially in application scenarios where weight reduction is required, aluminum extrusion profiles perform particularly well.

Excellent corrosion resistance: Aluminum material naturally has oxidation resistance, aluminum extrusion profile surface will form a dense layer of oxide film, has a strong corrosion resistance.

Precision machining and high design flexibility: Aluminum extrusion allows the manufacture of complex geometries and a variety of cross-sectional designs. Through precise die control and production processes, customized aluminum profiles can be produced to meet customer needs.

High production efficiency and batch production capacity: Aluminum extrusion's fast production speed and stable production process allow for the production of standardized or customized aluminum profiles in large quantities and at high speeds, adapting to the market's demand for high efficiency and low cost.

Good processing performance: aluminum extrusion profiles have excellent processability, can be easily cut, welded, bent, punched and other secondary processing to meet the complex processing needs of different industries.

Advantages of Aluminum Extrusion from LEADMKAE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across the World

Fast Delivery Across the World

Common Specifications and Profiles of Aluminum Extrusions

Aluminum extrusion profiles can be produced in different cross-sections depending on the application requirements, such as:

Square and rectangular tubes: widely used in construction, transportation, industrial equipment, etc.

Angle and T profiles: widely used in frame structures, bracket systems, etc.

Round tubes and round bars: used in structural components, electrical industry, etc.

Customized profiles: customized aluminum profiles in various shapes according to customers' design requirements, such as radiator profiles, decorative profiles, etc.

Aluminum Extrusion Surface Finishing Options

Different surface treatments not only enhance the appearance of aluminum extrusions, but also increase their durability and ability to adapt to different environments. The selection of the appropriate surface treatment will be determined by factors such as the final application needs, cost control and environmental requirements.