Search

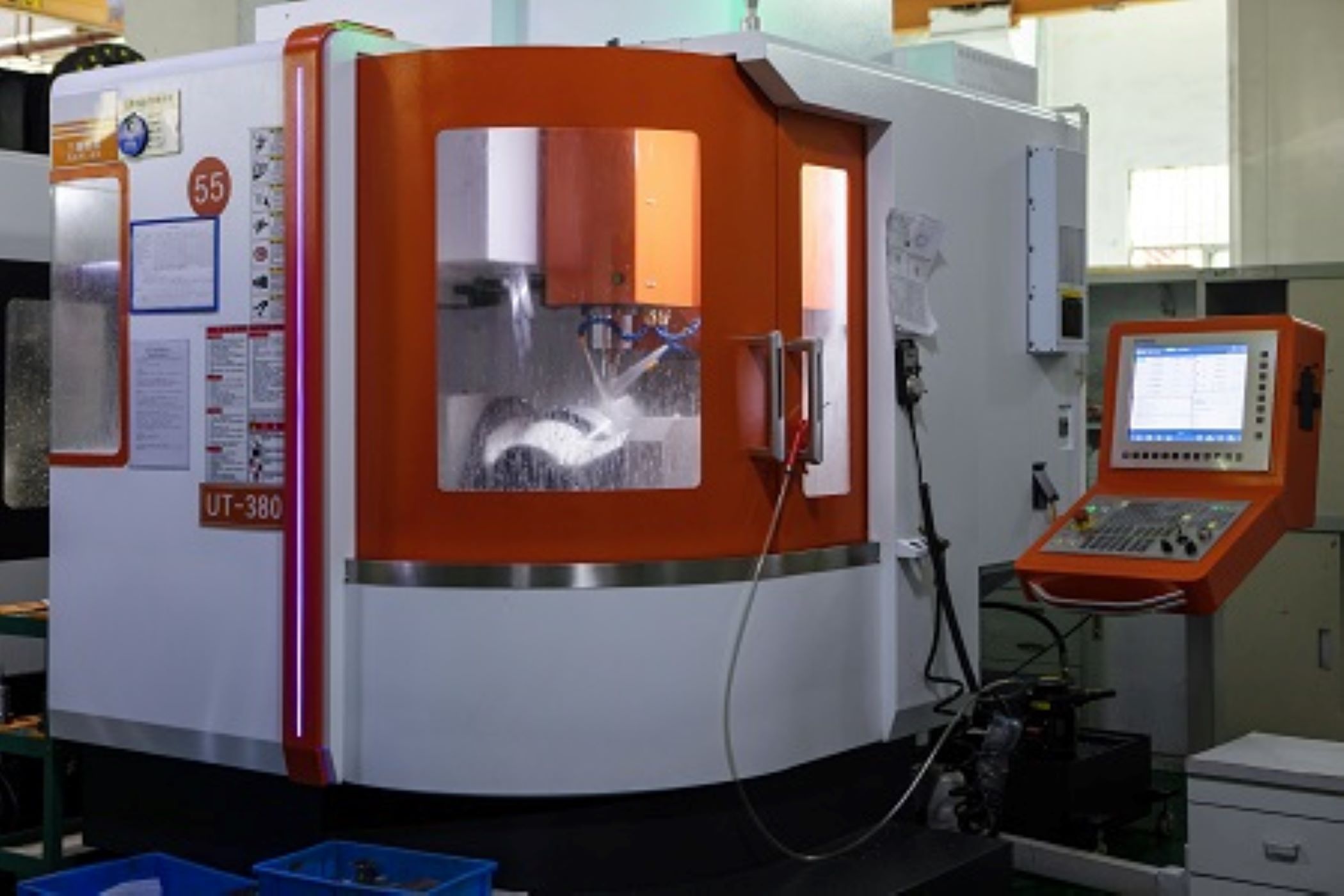

CNC Machine

Through computer-controlled machines to perform complex cutting, milling, turning and other machining operations. the main features of CNC machining instruments are high precision, high efficiency and automation, which are widely used in aerospace, automotive, mold manufacturing, medical equipment and many other industries.

1. CNC milling machine (numerically controlled milling machine)

A CNC milling machine is a device used to cut materials (e.g., metals, plastics, wood, etc.), usually by means of a rotary tool. It is capable of performing complex milling, drilling, boring, and cutting operations, and is suitable for machining parts with a variety of shapes.

Features:

High precision and complex shape machining capability.

It can be used to machine various complex shapes such as flat surfaces, curved surfaces, beveled surfaces, and internal and external threads.

Equipped with multiple tools that can be automatically changed according to machining needs.

2. CNC lathe (numerical control lathe)

CNC lathe is used for cutting and machining of rotating workpieces, mainly to complete the machining of external, internal, conical, end face and other shapes. It is usually used to process parts with rotationally symmetrical shapes, such as shafts, disks, sets, etc.

Features:

High precision, suitable for machining round and symmetrical parts.

High degree of automation, automatic tool change, feed control and other operations are possible.

Multi-axis machining can be realized to improve productivity.

3. EDM

EDM uses an electric spark discharge between the electrode and the workpiece to generate high temperatures, melting and removing metal from the workpiece. It is suitable for machining materials with high hardness, complex shapes, and difficult to machine.

Features:

Very hard materials can be machined.

High precision, suitable for complex and fine internal cavity machining.

No stress on the material, avoiding thermal deformation.

4. CNC Milling and Turning Compound Machine (CNC Milling and Turning Integrated Machine)

CNC milling and turning composite machine combines the functions of milling machine and lathe, it can complete milling and turning operations on the same machine, which greatly improves the machining efficiency and avoids the errors brought by transferring workpieces between different equipments.

Features:

With dual functions of milling and turning.

Highly automated, suitable for comprehensive processing of complex parts.

Multi-axis operation improves machining accuracy and efficiency.