Search

Using advanced techniques and sophisticated machines to meet your specific needs

Die Casting

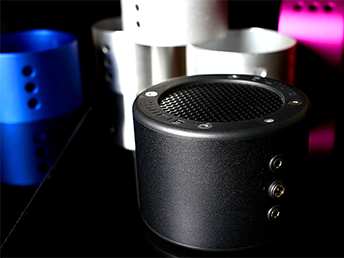

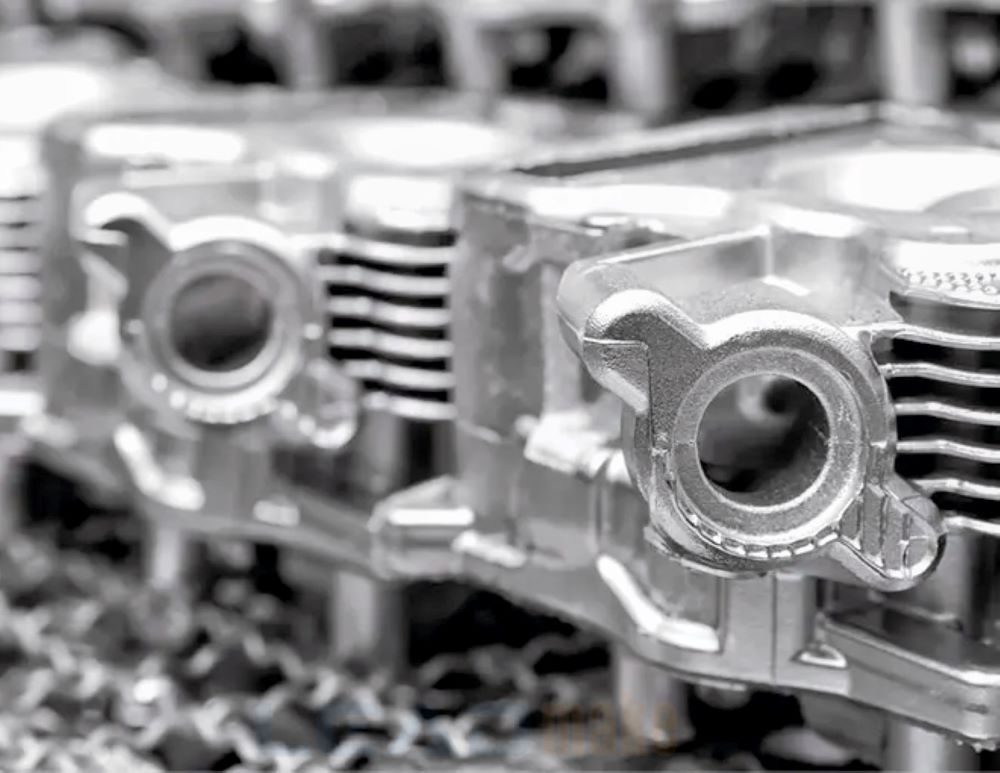

Die casting is a manufacturing process in which molten metal is injected into a mold cavity under high pressure, and is widely used to produce metal parts with complex shapes and high precision requirements. Typically, light alloy materials such as aluminum, zinc and magnesium are commonly used metals in die casting, and they have a wide range of applications in industries such as automotive, electronic equipment, machinery and consumer goods.

Welcome to learn about our die casting services! Our company is committed to providing high-quality, high-precision die casting solutions for a wide range of industries. Whether you are an automobile, electronics, home appliances, or other areas of business, we can provide the most suitable die casting products and services according to your needs!

Advantages of Die Casting

The die casting process offers many advantages, especially when it comes to producing complex shapes and high-precision metal parts in large quantities. The following are some of the main benefits of the die casting process:

High precision and quality

Suitable for mass production, high productivity

Suitable for the production of complex shaped parts

Excellent surface quality of the casting

Saving materials

Improve the consistency of production

Reduce processing costs

Advantages of Die Casting from LEADMAKE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across the World

Fast Delivery Across the World

Our Die Casting Service Process

Consultation and Needs Analysis: We first communicate with customers in detail to understand your project requirements and product specifications.

Product Design and Mold Development: Our engineers will provide optimized designs according to the requirements and make high-precision molds to ensure efficient production.

Production and Quality Control: During the production process, we strictly monitor each process and conduct multiple rounds of testing to ensure product quality.

Delivery and after-sales service: We provide perfect after-sales service to ensure that your die-casting products can be put into use smoothly, and continue to provide technical support for you.

Avabiliable Die Casting Materials

Different die casting materials have their own unique advantages, and the selection of the right material depends on the application area of the part, performance requirements, weight requirements and production costs. Aluminum alloys, zinc alloys and magnesium alloys are the most common materials used in die casting, and are widely used in the automotive, electronics and home appliance industries. At leadmake, our commonly used materials are as follows and we can also choose materials to produce products according to your needs:

zinc

copper

aluminum

magnesium

lead

tin

lead-tin alloys

Customized Surface Treatment