Search

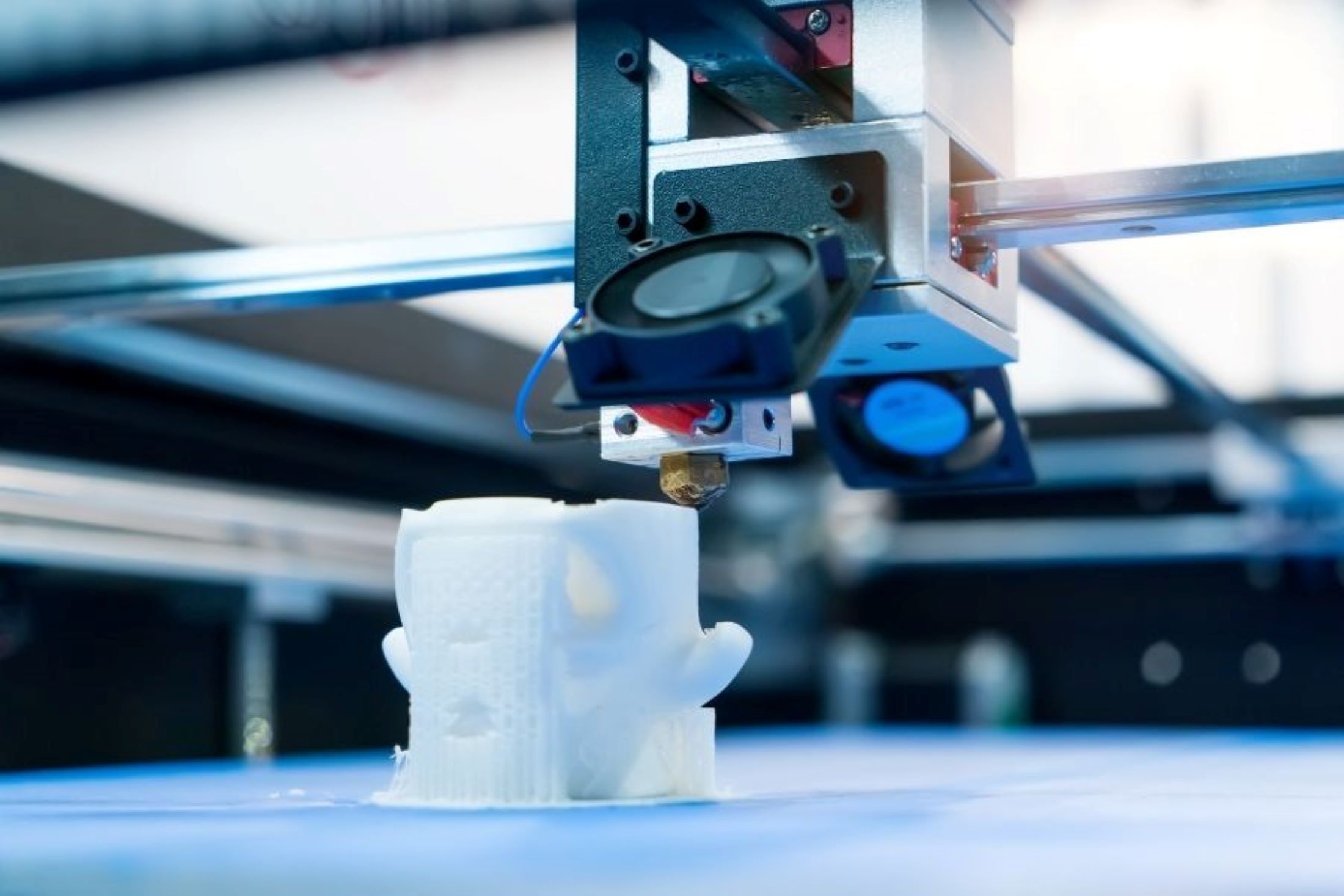

Innovations in 3D Printing and Additive Manufacturing Technologies Drive the Future of Rapid Prototyping and Parts Processing

As technology continues to evolve, "3D printing" and "additive manufacturing (AM)" are redefining the way rapid prototyping and parts machining is done. Particularly in the aerospace, automotive, medical and consumer electronics sectors, these technologies are not only improving productivity, but also making the realization of customized and complex designs more feasible.

Key development trends:

1. Multi-material 3D printing technologies

Next-generation 3D printing technologies are able to print using multiple materials at the same time, greatly increasing production flexibility and precision. Manufacturers can combine materials such as plastics, metals, and ceramics in the same process to respond to the performance requirements of different parts.

2. Higher production speed and accuracy

The accuracy and printing speed of modern additive manufacturing equipment has improved significantly, and some systems have been able to produce complex parts within hours, which is very beneficial for prototype development and small batch customized production.

3. Smart manufacturing combined with automation

The combination with Artificial Intelligence (AI) and Internet of Things (IoT) technologies has made the process of additive manufacturing smarter. The addition of automated production lines and real-time monitoring systems makes the production process more efficient and precise.

4. Parts remanufacturing

Additive manufacturing technology has also shown great potential in the field of parts remanufacturing, especially in the aerospace and automotive sectors, saving a lot of cost and time by reprinting damaged or worn parts.

Industry outlook:

The field of prototyping and parts processing is moving toward greater customization, automation, and sustainability as more companies adopt additive manufacturing, especially high-precision 3D printing technologies. These technologies are expected to continue to drive productivity gains and have a profound impact on traditional manufacturing processes in the coming years.