Search

Medical

Medical Field Service

As a leading rapid prototyping and parts machining company, we understand that the medical industry demands a high level of precision, reliability and compliance. We are committed to providing medical device manufacturers, medical device suppliers, and research institutions with high-quality prototyping and component fabrication services to ensure your products meet stringent industry standards and performance requirements.

Our medical field services cover the entire lifecycle from conceptual design to final product, providing comprehensive technical support and quality machining solutions.

Our services in the medical field

1, Medical Device Prototyping

Rapid and accurate prototyping is critical in the development of medical devices. We provide high-precision prototyping services to help accelerate product design validation and functional testing.

2. Customized medical component machining

We provide high-precision machining services for medical devices and instruments, ensuring that each part meets strict quality standards. Whether it's a single small batch or a complex precision part, we can provide you with the most suitable solution.

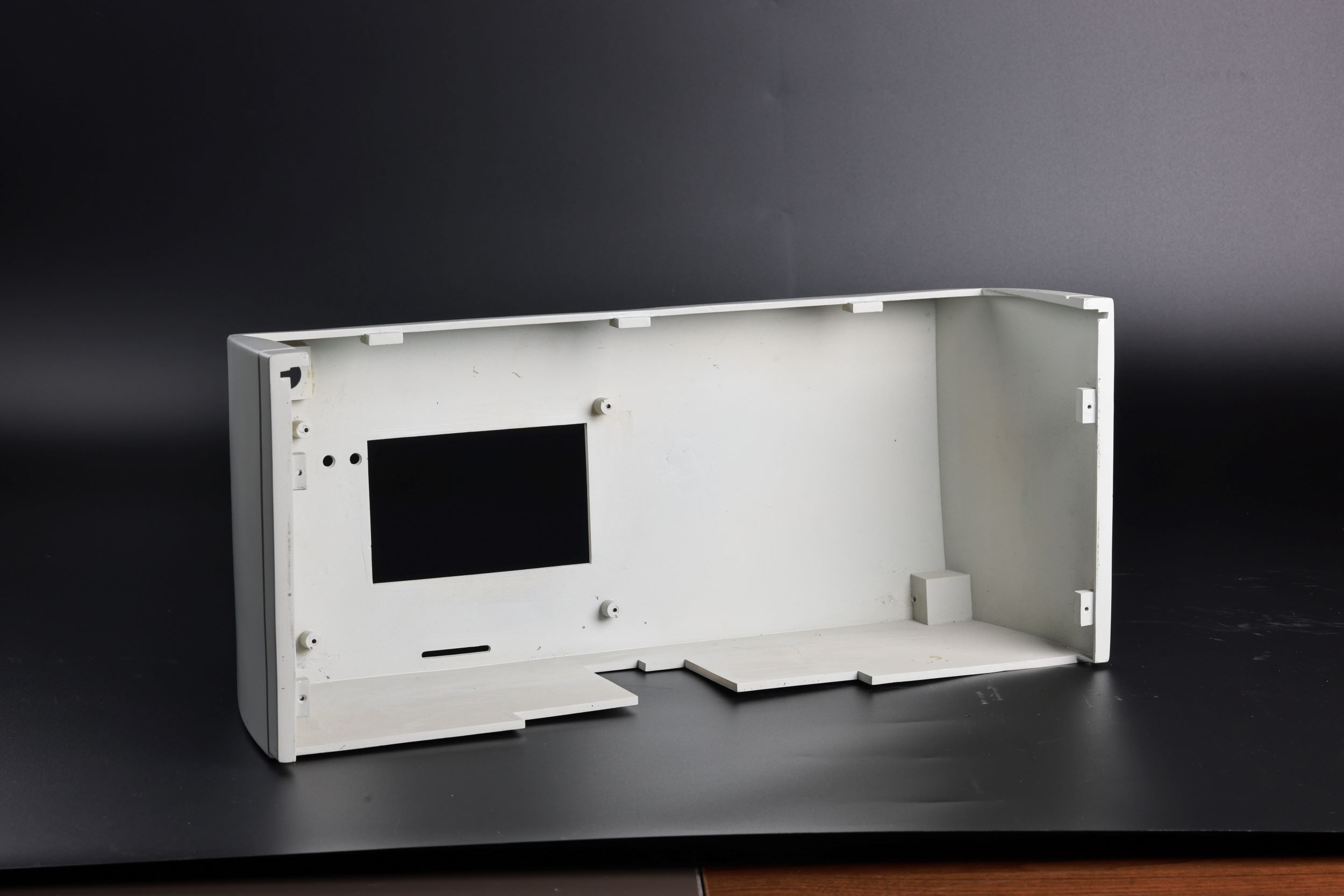

3. Processing of medical device housings and structural components

We provide design and machining services for medical device housings and structural components. Our housings and structural components are designed with a focus on light weight, high strength and durability.

4. Biocompatibility and medical certification support

To ensure that our products meet the stringent standards of the medical industry, we provide material selection and certification support to ensure that the parts produced have the necessary biocompatibility and comply with relevant regulatory requirements.

5. Customized solutions and technical support

During the development of medical devices, we work closely with our customers to provide technical support throughout the entire process, from product design to manufacturing. Whether it is personalized requirements, design optimization or mass production, we can provide customized services according to customer needs.