Search

Rapid Prototyping Industry Sees a Peak of Innovation, Driving Transformation and Upgrading of the Manufacturing Industry

As technology continues to advance, the rapid prototyping manufacturing industry is entering an unprecedented innovation peak. In recent years, the rapid development of advanced technologies such as 3D printing and additive manufacturing has greatly boosted the progress of this industry. Especially in the field of rapid prototyping, manufacturers and designers are leveraging these technologies to break through the limitations of traditional manufacturing and accelerate product development and production cycles.

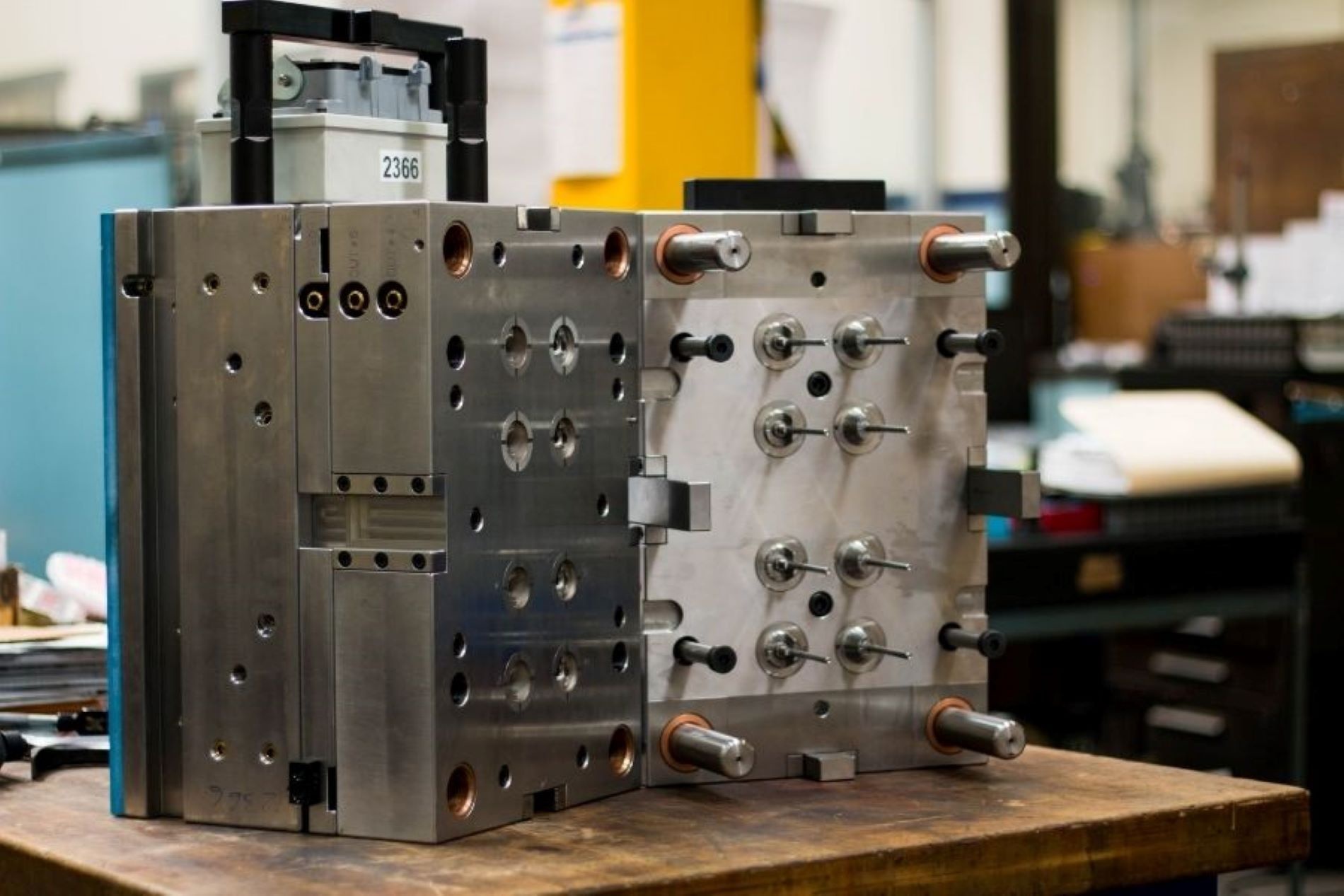

Rapid prototyping, also known as “rapid tooling,” is designed to produce a physical model of a product or initial part in a fast and efficient manner. The technology is used in a wide range of industries, including automotive, aerospace, medical devices, and consumer electronics. Compared with traditional manufacturing processes, rapid prototyping can not only significantly reduce product development time, but also significantly reduce development costs. In recent years, with the maturity of 3D printing technology and the continuous expansion of the scope of application, the application scenarios of rapid prototyping have become more diverse. From original design verification, functional testing to the production of customized parts, rapid prototyping is gradually moving towards industrialization and standardization. Experts point out that the future of rapid prototyping is not only a tool, but also a key driving force to promote innovation, improve production efficiency and product quality.

Technology development to lead the industry trend

At present, additive manufacturing technology has become the mainstream of the rapid prototyping industry. Compared to traditional subtractive manufacturing, additive manufacturing allows for layer-by-layer stacking of materials based on digital models, which allows for more complex and personalized designs for parts. In addition, technologies such as light-curing resins, metal printing, and ceramic printing are breaking through, bringing more possibilities to manufacturing.

For example, automakers have begun to use 3D printing technology for customized parts, which not only greatly shortens the production cycle, but also enables the production of complex parts at a lower cost. The aerospace industry is also gradually applying 3D printing technology to produce key components for aircraft, further enhancing their performance and safety.

Industry Chain Synergy for Market Growth

The wide application of rapid prototyping technology has also led to the synergistic development of the industry chain. From the supply of raw materials, research and development of equipment to the optimization of software design, the entire industry chain is constantly innovating and evolving. As the industry's demand grows, more and more companies are plunging into this field, creating a diverse and dynamic market.

For example, some startups are focusing on providing industry-specific customized rapid prototyping services that cater to customers with specific needs. At the same time, traditional manufacturing companies are also actively upgrading their technology, using advanced prototyping techniques to optimize the product design process and improve productivity.

Challenges and Opportunities

Despite its promising future, the rapid prototyping industry is also facing a number of challenges. On the one hand, the high cost of equipment, technical thresholds, and raw material constraints remain bottlenecks to the industry's development. On the other hand, with the increase in market demand, how to balance the contradiction between customized production and large-scale manufacturing, and how to deal with the quality control problems that may be encountered in the production process are also urgent issues to be resolved.

However, with the continuous progress of technology, these problems are expected to be alleviated in the next few years. Experts believe that with the introduction of artificial intelligence, big data and IT technologies, future rapid prototypes will be more intelligent and capable of fully automated design and production processes, further promoting the digital transformation of manufacturing.

Conclusion

The development of rapid prototyping technology not only promotes the innovation of the product development process, but also provides a new impetus for the transformation and upgrading of the traditional manufacturing industry. With the continuous progress of industry technology and the gradual expansion of market demand, rapid prototyping industry is expected to usher in more prosperous development opportunities in the coming years.

In this era full of challenges and opportunities, rapid prototyping is becoming an important driver of manufacturing innovation, promoting the intelligence and modernization of global industry.