Search

Providing Metal Stamping, Punching, Cutting,Bending and Welding services for your custom products

Custom Sheet Metal Service

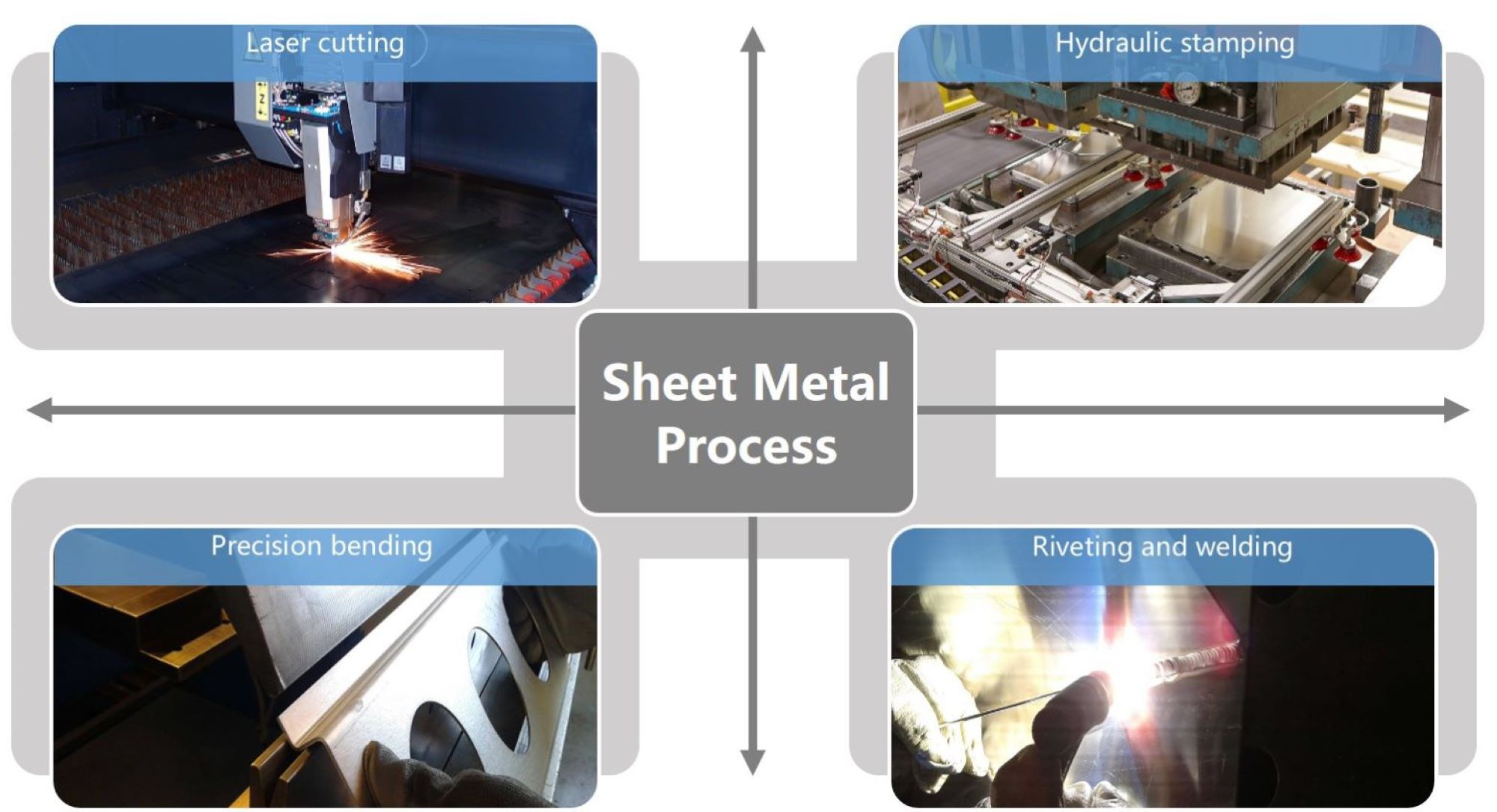

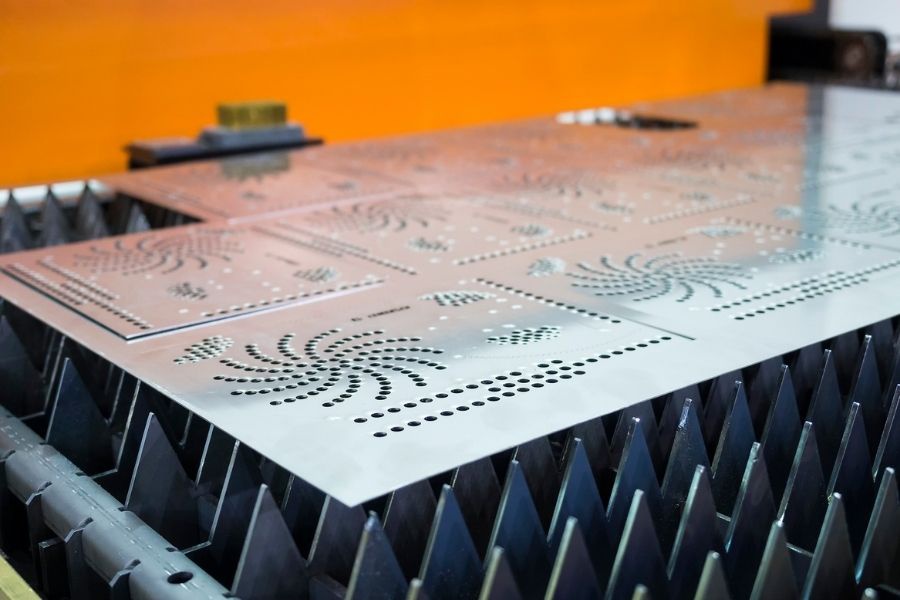

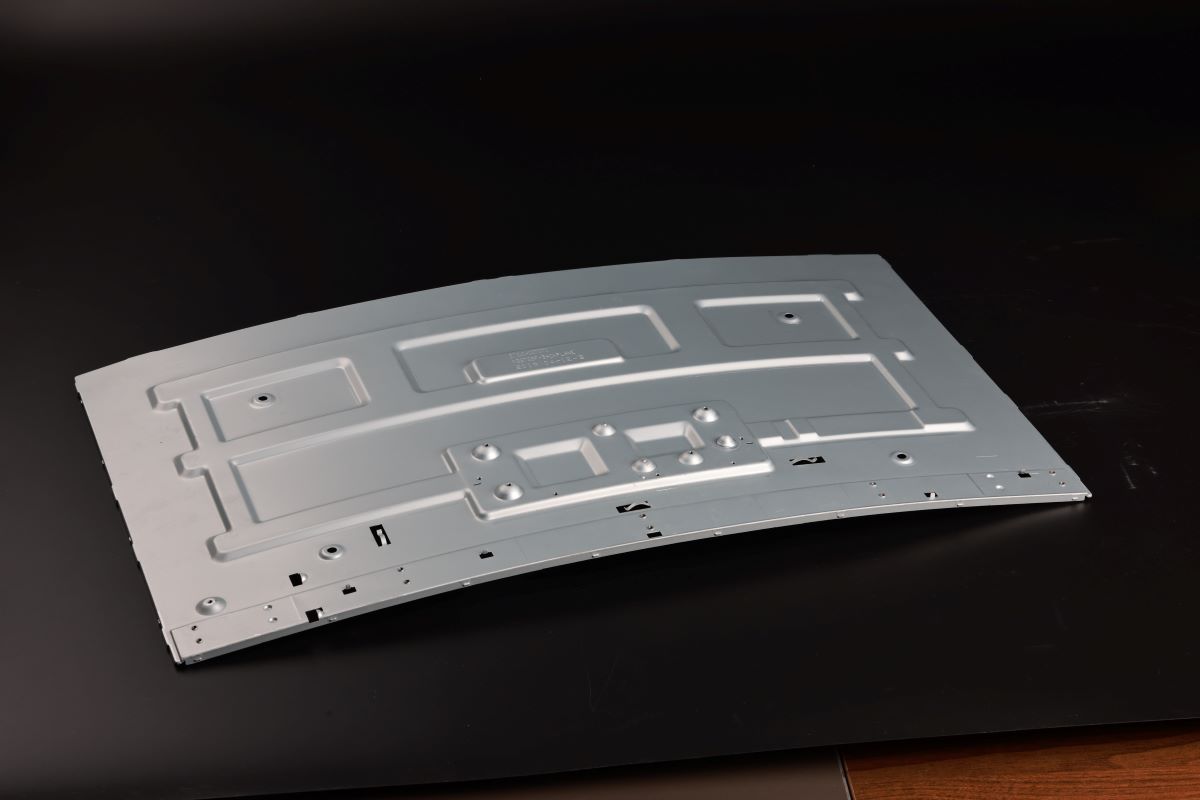

Sheet metal is a comprehensive cold working process for thin metal sheets (usually under 6mm), including shearing, punching, cutting, compounding, folding, riveting, splicing, molding, etc. The process is characterized by the consistent thickness of the same part. Its distinctive feature is the consistent thickness of the same part. Sheet metal is characterized by light weight, high strength, electrical conductivity, low cost, and good performance in mass production, and is widely used in the fields of electronics and electrical appliances, communications, automotive industry, and medical devices.

Our sheet metal processing team has stable and mature process design, hydraulics, bending, and cutting. The biggest feature is the simplification, speed, and cycle of the production process, which can fully meet customers' processing of samples, especially suitable for small batches of diversified parts.

Advantages of Sheet Metal Fabrication:

As the application of sheet metal becomes more and more widespread, the design of sheet metal parts becomes a very important part of the product development process. It has the following main advantages:

High efficiency and fast delivery

Flexible and variable pricessing capability

strict quality control system

Diversified processing techniques

Cost control and material utilization

High precision

Flexible material selection

Customized services

Advantages of Sheet Metal Fabrication from LEADMAKE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across the World

Fast Delivery Across the World

We strictly demand ourselves and constantly improve ourselves to meet our customers' needs with strong production capacity and high quality service.

Tolerance Standards:

| Laser Cutting |

Metal sheet laser cutting is controlled within 0.10mm. |

| Bending |

Bending is normally controlled within 0.30-0.50mm. |

| Welding |

Welding parts can be controlled generally within 0.30-1mm. |

|

Hole Tolerances for Precision Sheet Metal |

The hole tolerances for precision sheet metal can be guaranteed at ±0.02mm. |

| Hole Position Tolerance |

Hole position tolerances are guaranteed at ±0.02mm. |

| Material Thickness |

Max. thickness 5mm Min. thickness 0.1mm |

Avaliable Sheet Metal Materials:

Aluminum Alloy

Stainless Steel

Cold-roll Steel

Mild Steel

Brass

Copper

Alloy Steel

Tianium Inconel

Invar and more

Customized Surface Treatment:

The purpose of surface treatment is to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product. Leadmake provide surface treatment services according to your specific specific needs. Some of the options are as follows:

-