Search

Providing SLA 3D Printing, SLS 3D Printing, PolyJet 3D Printing,Surface Finish and Assembly

Customized 3D Printing

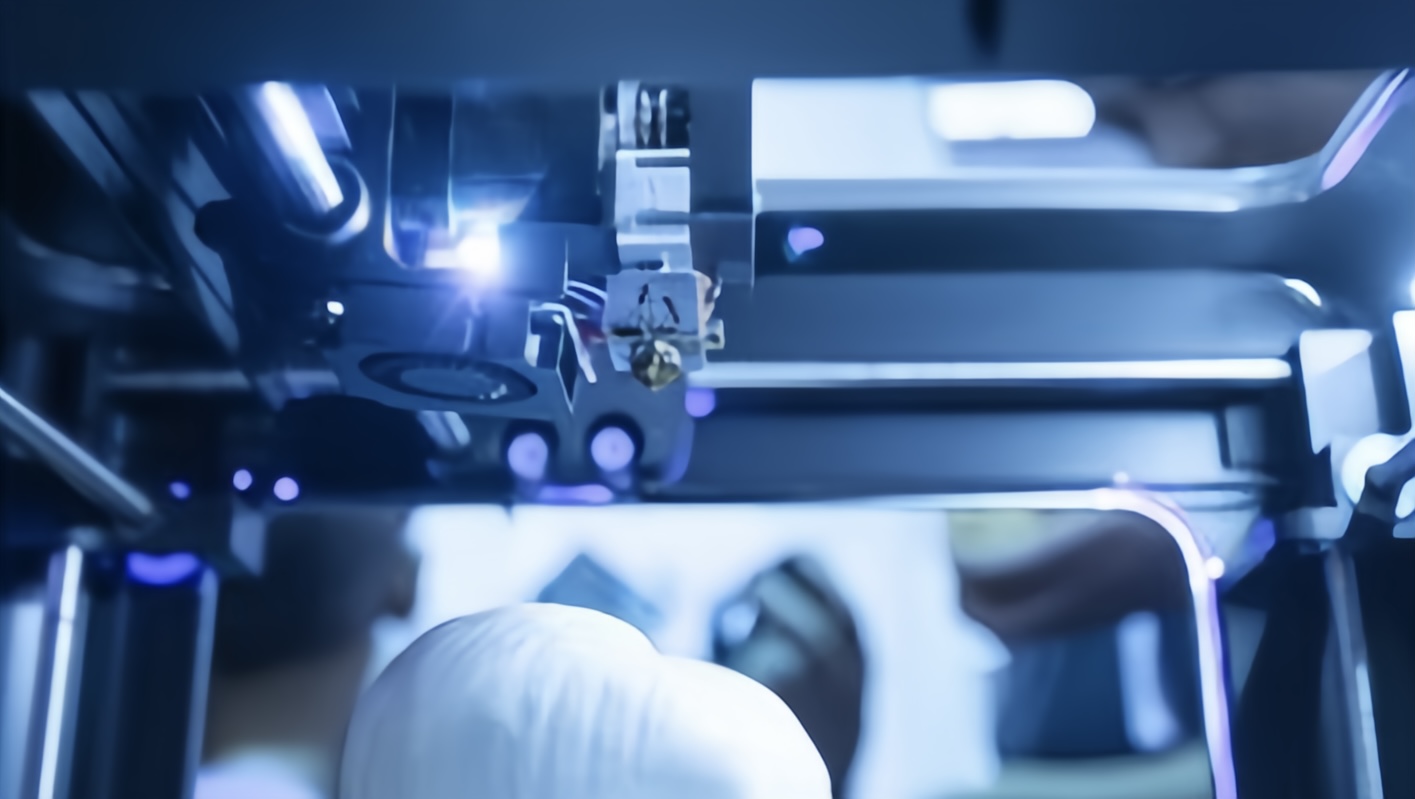

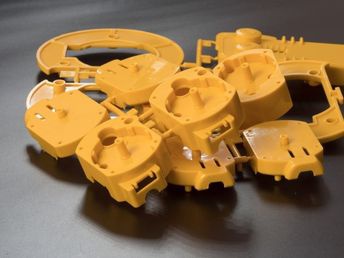

3D printing (also known as additive manufacturing) is a technology that creates three-dimensional objects by stacking materials layer by layer. This technology generates three-dimensional models through computer-aided design (CAD) software, and then transforms those models into physical objects through a printer. Unlike traditional subtractive manufacturing techniques (e.g., milling, cutting), 3D printing creates complex structures by continually adding material to an object.

Welcome to our company's 3D printing services page! We specialize in providing high-quality, innovative and personalized 3D printing solutions to help you achieve design and production breakthroughs in a variety of industries. Whether it's a proof of concept, product prototyping, or small batch custom production, we can provide you with comprehensive support.

Advantages of 3D Printing

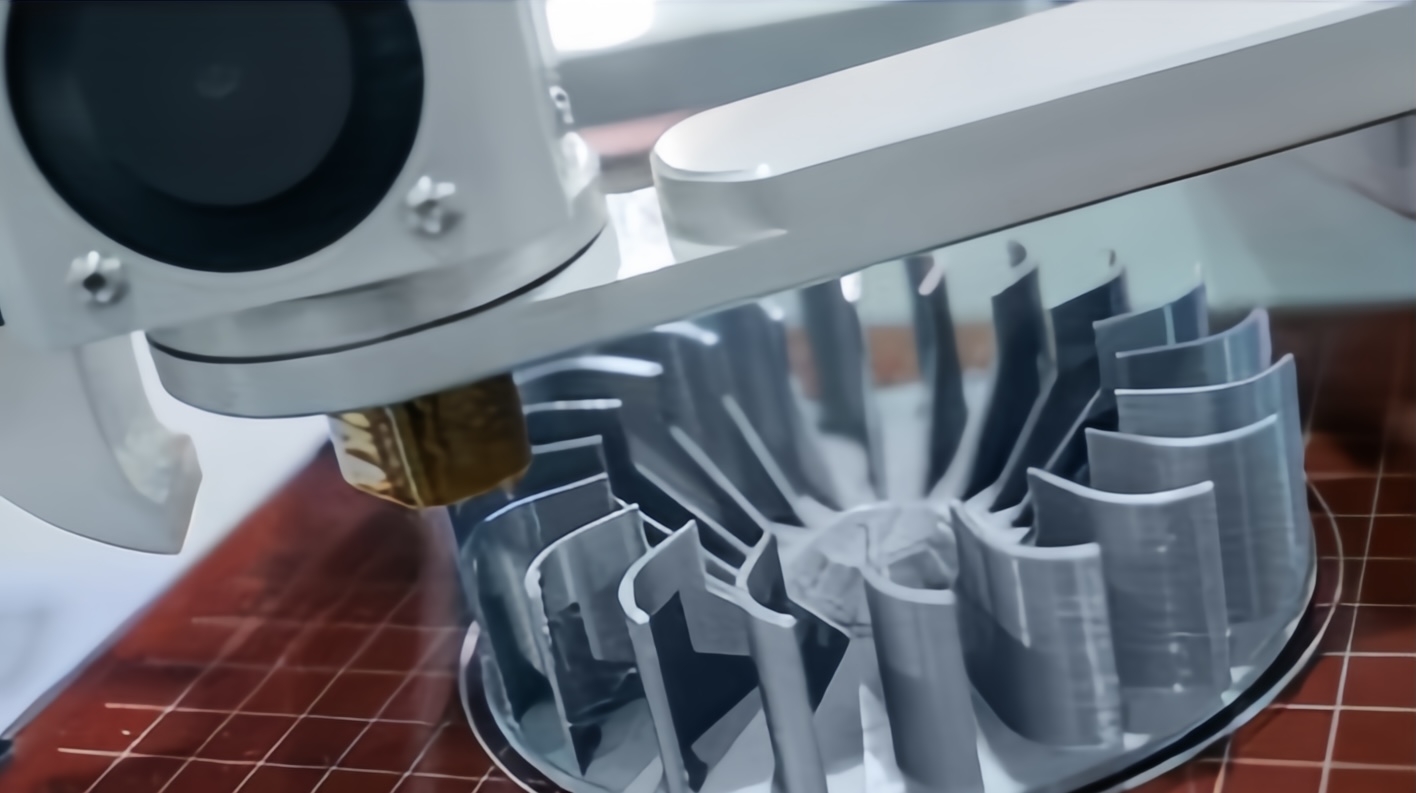

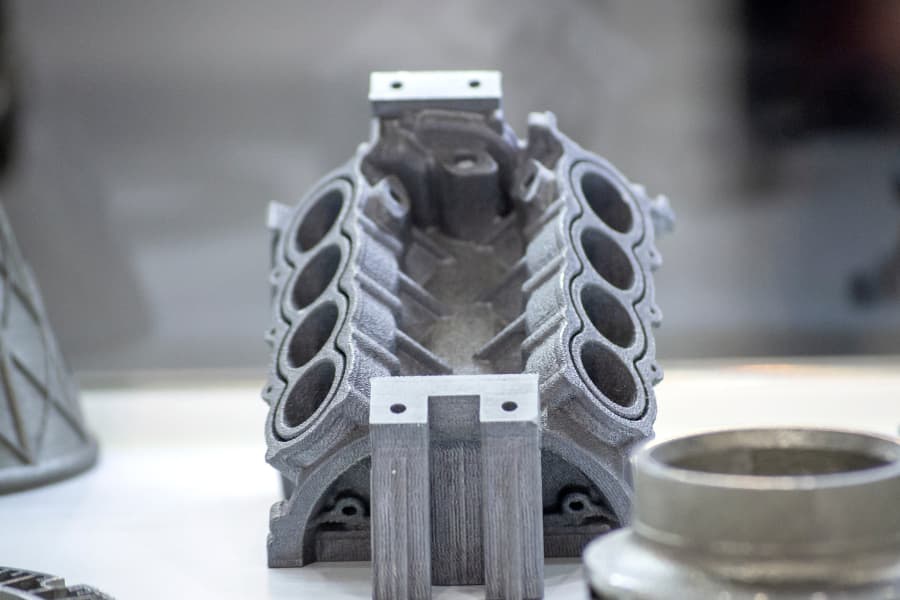

High-complexity parts: 3D printing can manufacture complex shapes and geometric structures that are difficult to achieve with traditional processing methods.

Rapid prototyping: 3D printing can quickly transform digital designs into physical prototypes, significantly reducing the product development cycle. It is very effective in quickly verifying design ideas and improving product characteristics.

Reduce costs: Because there is no need to make molds, tools or complex production lines, 3D printing for small batch production and customized products in particular have cost advantages.

Personalization: 3D printing can provide highly customized products according to customer needs, from custom accessories to personalized gifts, to meet different market needs.

Small batch production: for small batch production, 3D printing has more advantages than traditional manufacturing methods. No need to invest in expensive molds or production lines, you can flexibly produce customized products.

Environmental protection and energy saving: for small batch production, 3D printing has more advantages than traditional manufacturing methods. Without investing in expensive molds or production lines, it is flexible enough to produce customized products.

Material diversity: 3D printing technology supports a variety of different materials, including plastics, metals, ceramics, resins, composites, etc., to meet the specific needs of different industries for materials.

Advantages of 3D Printing from LEADMAKE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across teh World

Fast Delivery Across teh World

Avabiliable 3D Matrerials

Different 3D printing materials have different physical and chemical properties. Depending on the printing process and application area, 3D printing uses a wide variety of materials, commonly including plastics, metals, and ceramics. The choice of each material depends on the desired physical properties, printing accuracy, and the final application.Here are some of the materials we commonly use:

Nylon(PA)

ABS

Polyethylene

Polycarbonate

TPU

PLA

PETG

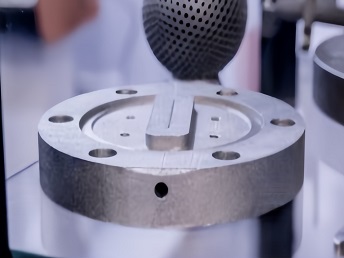

3D Printing Parts Surface Finishing Options

While 3D printing can create parts with complex shapes and exquisite detail, printed objects often require further processing to improve appearance, enhance performance, or increase durability.

Our 3D Printing Services