Search

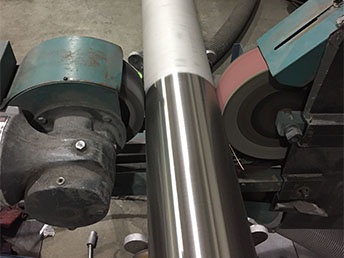

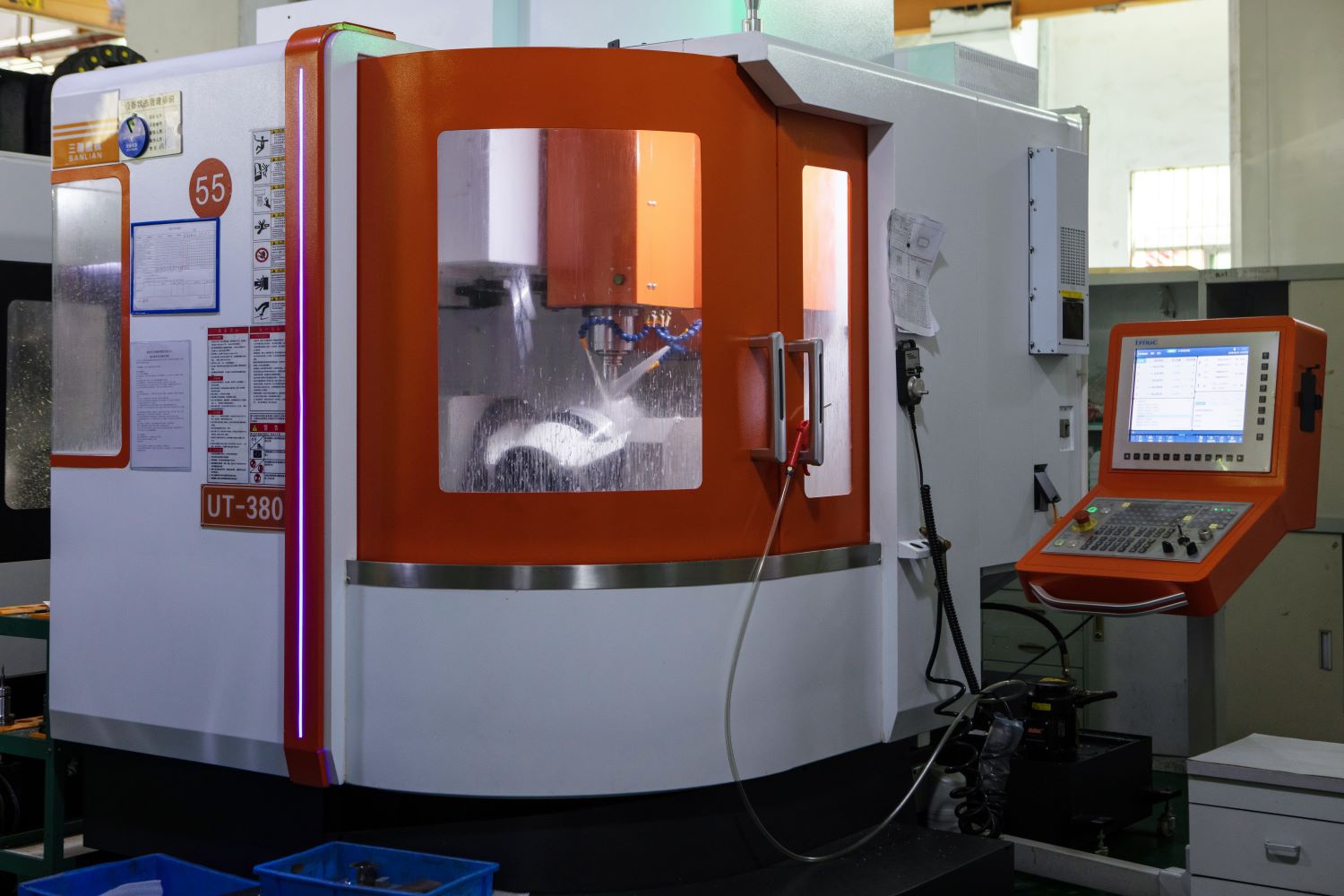

CNC Turning, CNC Milling, CNC Drilling, CNC Cutting, CNC Grinding, 5-axis CNC machining, Wire EDM Machining

CNC Machining Service

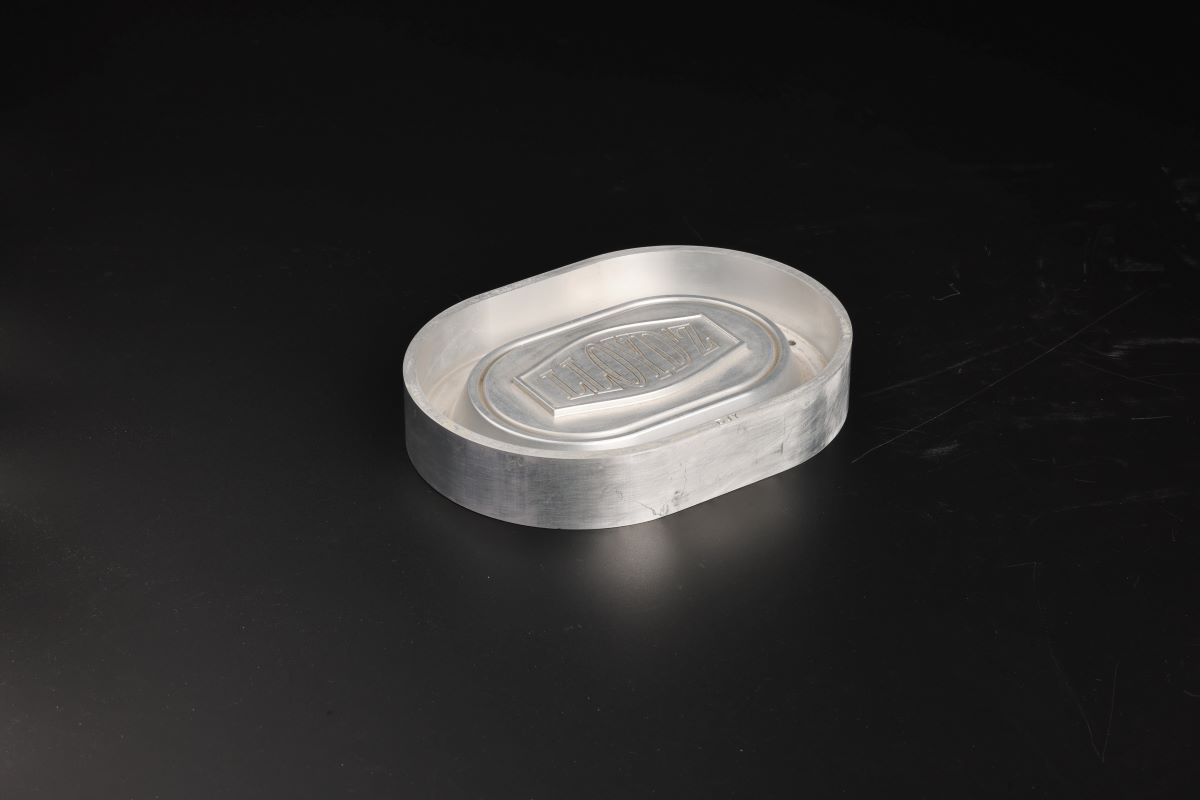

CNC machine tools can automatically process any products and parts directly in accordance with the program prepared by technicians in advance. This is what we call "computer numerical control machining". CNC machining is widely used in any field of all machining, and is an important and necessary technical means for mold processing.

With more than 15 years of machining experience, we can produce CNC machined parts to your specifications. Our team of professionals will work with you throughout the design and production process to provide you with the parts you need at a cost that suits you.

Advantages of CNC Machining Service:

1, CNC machining does not require complex tooling. If you want to change the shape and size of the part, you only need to modify the part machining program, which is suitable for new product development and restyling.

2, CNC machining quality and stability, high machining accuracy, high repeatability, to adapt to the processing requirements of high-precision products.

3, High productivity can significantly shorten the production cycle and improve productivity.

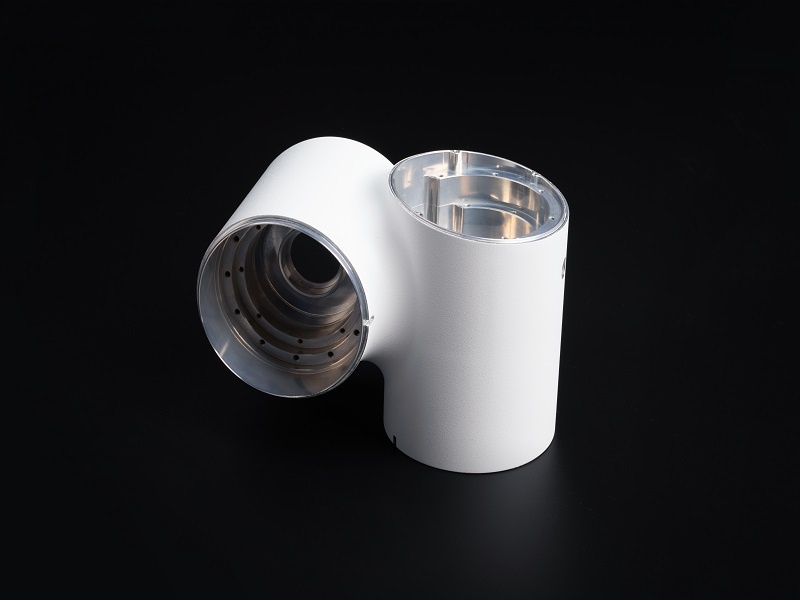

4, It can process complex surfaces which are difficult to be processed by conventional methods, and even process some unobservable machining parts.

5, It can realize automatic production, reduce manual intervention, reduce labor costs, accurate processing to reduce material waste, improve utilization, reduce production costs.

Advantages of CNC Machining from LEADMAKE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across the World

Fast Delivery Across the World

Tolerance Standards:

We can offer you specify available tolerance according to ISO 27968-mk.

| Max Dimensions | 1600mm x 1200 mm x 900 mm |

| Linear Dimension | +/-0.005mm |

| Hole Diameters(not reamed) | +/-0.005mm |

| Shaft Diameters | +/-0.005mm |

| Burrs and Chamfers | Deburring by default, chamfering according to your requirements |

Avaliable CNC Machining Materials:

Product materials are also an important part of the analysis when evaluating the needs of a partner's CNC machining project. It is important to consider the properties of various materials and how they affect performance, cost and lifespan. According to your project, we will recommend the most suitable and economical materials (not limited to the following materials) and production methods to produce your parts.

Metal and alloy:

Alloy Steel

Mild Steel / Low Carbon Steel

Tool Steel

Stainless steel

Copper

Brass

Aluminum Alloys

Titanium and more

Plastic:

ABS

PA(Nylon)

PC

PE

PET

PMMA(Acrylic)

POM (Acetal)

PP

PTFE

PEEK and More

Glass&Fibers:

Perspex

styrodur glass

glass fiberboard

aramid fiberboard

carbon fiberboard

Customized Surface Treatment:

The surface treatment process is an indispensable part of the manufacturing industry, which can improve the corrosion resistance, wear resistance, aesthetics and other properties of the parts, thereby improving the quality and service life of the products.