Search

Plastic injection molding, Plastic overmolding, Plastic insert molding, Silicone rubber injection molding, Die casting tooling

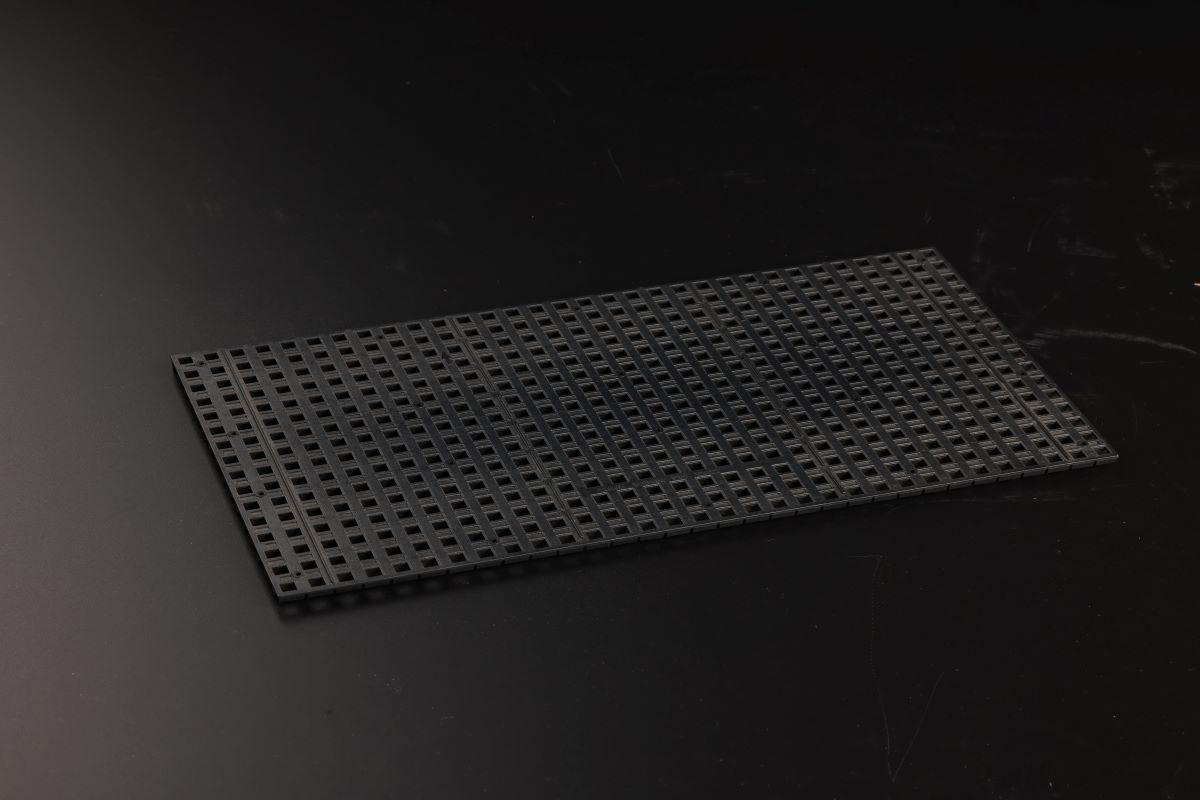

Customized Injection Molding

Injection molding is a method of producing shapes for industrial products, which is mainly used for manufacturing various plastic products. Through the injection molding machine will be thermoplastic or thermosetting plastic melting into the mold, after cooling and curing to get molded products. Injection molding has the advantages of fast production speed, high efficiency, operation can be automated, etc., suitable for mass production and the processing of complex shaped products.

LEADMAKE provides high-precision and high-quality custom injection molding services to meet the needs of a variety of industries, including medical, consumer electronics, automotive, home appliance and industrial manufacturing. With advanced injection molding technology and equipment, we are able to produce complex and demanding injection molded parts, ensuring that every product meets our customers' specifications and quality standards.

Advantages of Injection Molding Service:

Injection molding services are widely used in mass manufacturing for its efficient and precise production. It can produce complex shapes and high-precision products quickly and consistently, ensuring consistent size and quality of each part. Injection molding also offers a wide range of material choices to accommodate different performance needs, and post-processing treatments, such as painting and plating, can be applied to enhance appearance and durability. Although initial mold costs are high, unit costs decrease dramatically as production volume increases, providing significant cost efficiencies that are ideal for high volume production and high quality control.

Advantages of Injection Molding from LEADMAKE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across the World

Fast Delivery Across the World

All molds have complete records, and there are standard operating procedures (SOP) for management. Each product in production follows SOP and SIP, along with quality system checks, ensuring the production of standardized products.

Tolerance Standards:

| Max. part dimensions | 400mm x 600 mm |

| Mold Cavity Tolerance | +/-0.01 mm |

| Molded Parts Tolerance | +/-0.05 mm per centimeter when considering shrinkage |

| Part Size Consistency | +/-0.1 mm |

| Injection Molding Machine Quatity | 30+ |

| Type of machine | Single color injection molding machine, 2K molding machine, 3k molding machine |

| Mold type | Choose different molds according to your project. |

Materials for Injection Molding

Plastic injection molding materials:

POM(Delrin/Acetal),

Nylon, ABS, Acrylic,

PC, PE, PS, PEEK, PEI,

TPE, TPU, PTFE (Teflon),

Polycarbonate, Polyethylene,

PVC, PMMA (Acrylic), PET, Polypropylene

Tooling Metals:

Tooling Steel(P20)

Carbon Steel (S50C)

Aluminum alloy

Copper alloy

NAK80

S136, S136H

718H, 738H

Customized Surface Treatment:

The surface finish is determined by your requirements. Some of the options are as follows: