Search

Quality

Insist on Quality First

“Providing products that meet strict quality standards” is not just a slogan, it is the foundation of our business and one of the key reasons why we have grown from our establishment in 2006 to our current size. Insisting on producing high quality products is what we have been doing.

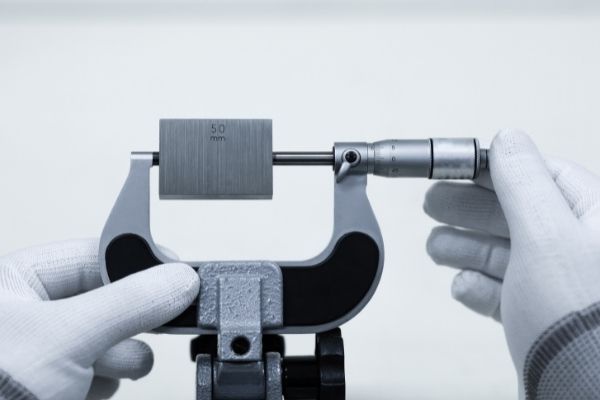

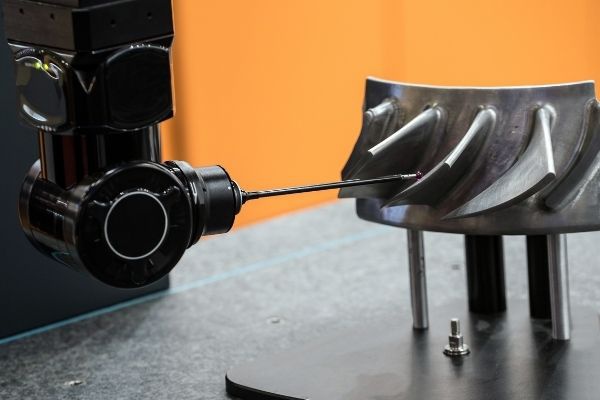

LEADMAKE has a full-process quality assurance chain and quality testing facilities to ensure the highest quality of all products, from metal and plastic materials to finished products. As an ISO certified company, it is our constant pursuit to manufacture and inspect products in accordance with strict quality control requirements. We utilize state-of-the-art quality inspection techniques and testing equipment in our factories, and are able to inspect the dimensions, hardness, tensile strength and elongation of workpieces throughout the production process.

Incoming Material Inspection:

All raw materials are carefully selected from our trusted and quality suppliers. All materials and compounds are subjected to stringent quality checks prior to storage or processing through the following processes:

Appearance Check

Dimension Check

Tensile Strength Test

Shore Hardness Test

First Article Inspection:

The first article inspection in the production process is to find out the factors affecting the product quality in the production process as early as possible, and to prevent batch defects or scraps. It is a means of pre-control of the production process, is an important method of quality control of the product process, is an enterprise to ensure product quality, improve economic efficiency of an effective and essential method. Usually in the following cases should be carried out in the first piece of inspection:

A batch of products when the start of production.

Equipment readjustment or major changes in the process.

Shift or operator changes.

Changes in the type of blank or material.

The first piece of qualified inspection before entering into formal production, mainly to prevent the occurrence of batch unqualified.

In-process Inspection:

Process inspection refers to the production process, the production of products (software, hardware, services, process materials, etc.) to a variety of quality control means according to the product process requirements of its specified parameters for testing and inspection, to achieve product quality control. The purpose is to prevent the generation of bulk nonconforming products and to prevent the flow of nonconforming products to the next process. It includes the first piece of inspection, inspection tour, the last piece of inspection.