Search

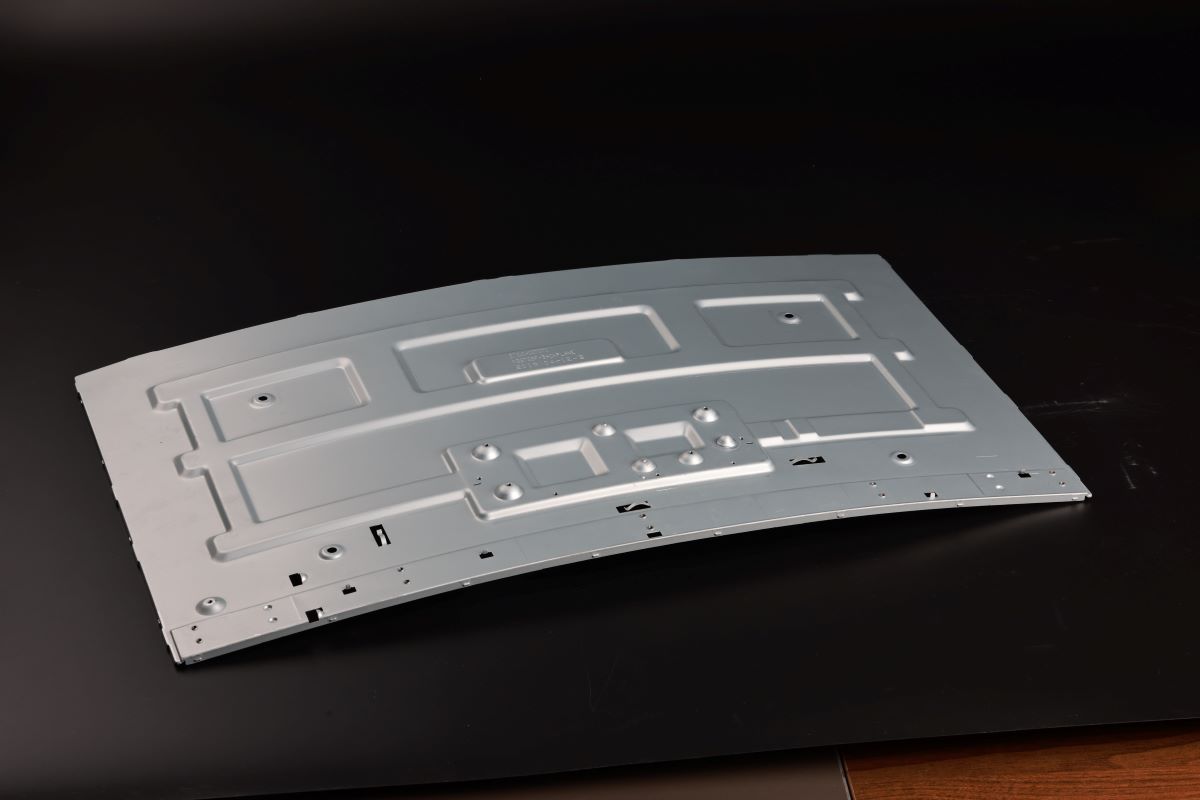

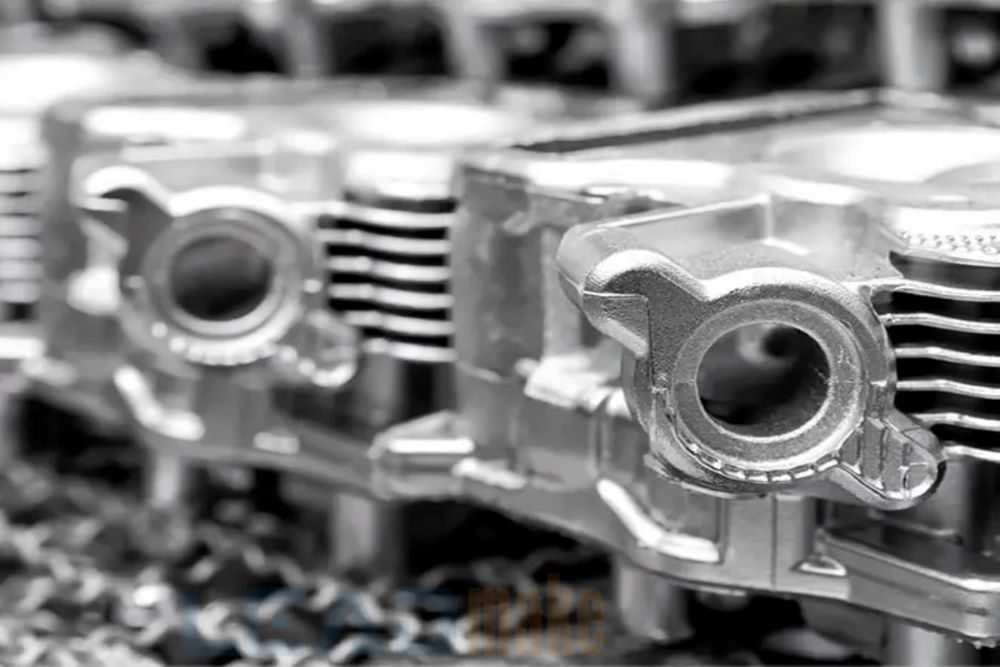

Urethane casting, Rapid tooling,Low-volum manufacturing, Rapid CNC machining, Rapid 3D printing, Rapid injection molding, Rapid sheet metal fabrication

Rapid Prototyping

Rapid prototyping can help you quickly validate your design, minimize development risk, and dramatically reduce time-to-market. With our advanced manufacturing technology and rich experience, we are able to provide you with high-precision and high-quality prototyping services to ensure that every step of your product from concept to realization is smoother. By choosing us, you will get professional, fast and cost-effective solutions to help your project succeed.

Our experienced engineers and state-of-the-art equipment can turn your idea into reality. We offer a full suite of rapid prototyping and low-volume manufacturing services, including rapid prototyping, CNC machining, sheet metal fabrication, injection molding, vacuum casting, die casting, 3D printing, aluminum extrusion, surface finishing, and assembly. Contact us now to get the prototype you want!

Advantages of Rapid Prototyping

Accelerate product development cycles

Accelerate product development cycles

Reduce development costs

Reduce development costs

Optimize design and functionality

Optimize design and functionality

Improve market competitiveness

Improve market competitiveness

Support small production

Support small production

Advantages of Rapid Prototyping from LEADMAKE

Reduce mold costs

Reduce mold costs

Improve development efficiency

Improve development efficiency

Avoid market risks

Avoid market risks

Rapid prototyping, a key tool in modern product development, helps companies accelerate innovation, optimize designs, reduce costs and improve product quality. It not only provides critical insights in the early stages of product development, but also provides a solid foundation for a successful launch of the final product. Through rapid prototyping, organizations can more effectively adapt to the market, improve customer satisfaction, and ultimately stand out in a competitive marketplace.

Prototyping Solutions