Search

Uilizing a diverse palette of polyurethane resins in vacuum casting process for your customized products

Vacuum Casting

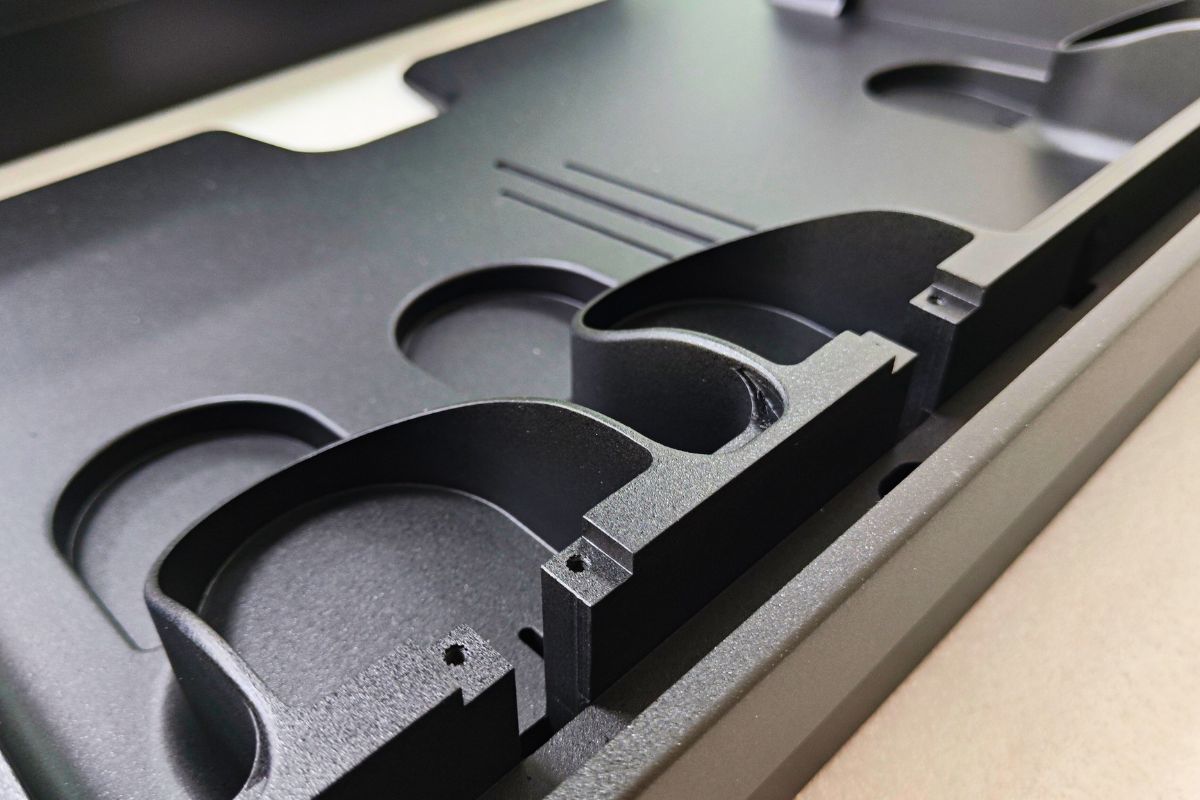

Vacuum casting is an advanced casting technology, which mainly injects liquid materials (e.g. polyurethane, silicone, etc.) into molds through a vacuum environment in order to prepare high-precision and high-quality prototypes, low-volume production parts, or small-volume customized products. With high molding accuracy, good surface quality and strong adaptability, vacuum casting is widely used in industrial design, rapid prototyping, automotive, aerospace, medical equipment, consumer electronics and other industries.

Vacuum casting enables the production of high-precision, complex structural prototypes, which are particularly suitable for parts with extremely high demands on detail and for small batches. Since the molds used are usually made of silicone or similar materials, there is no significant wear and tear on the molds during the vacuum casting process. Compared to traditional casting or injection molding processes, the vacuum casting process allows for low volume production at a lower cost and does not require complex injection molds, making it suitable for rapid prototyping and small batch custom production.

Advantages of Vacuum Casting

High precision and quality: Vacuum casting enables the manufacture of highly accurate, high surface quality parts for applications with stringent requirements for detail.

Rapid prototyping: Compared to traditional manufacturing methods, vacuum casting can significantly shorten the product development cycle, quickly produce prototypes and test them.

Cost-effective: Vacuum casting is cost-effective for small series and customized products, and is particularly suitable for pilot production.

Fidelity of complex shapes and details: Vacuum casting reproduces every detail of the mold very accurately, especially for complex shapes and products with high precision requirements.

Applicable to a wide range of materials: According to the customer's needs, vacuum casting can choose different types of materials (e.g. soft materials, hard materials, transparent materials, etc.) for production to meet the special needs of different fields.

No mold loss: Since the molds used are usually silicone or similar materials, it will not cause large-scale mold loss, which further reduces the production cost.

Advantages of Vacuum Casting from LEADMAKE

Customized Service

Customized Service

Certificate Quality Assurance

Certificate Quality Assurance

Fast Delivery Across the World

Fast Delivery Across the World

Tolerance Standards

| Standard Tolerance | ±0.3% (with a lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

| Minimum Wall Thickness | To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

| Maximum Part Dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

| Typical Quantities |

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

Avabilibale Vacuum Casting

Depending on the usage environment and performance requirements, we can provide our customers with a wide range of material choices, such as polyurethane, silicone, resin, rubber and so on. The following are some of the materials we offer:

Polypropylene (PP) like (80D)

Polycarbonate (PC) like (75D)

Acrylonitrile Butadiene Styrene (ABS) like (83D)

PE-like (65D)

Santoprene-like

Thermoplastic Polyolefins (TPO or TPE-O) like

Talc-Filled Polypropylene like

Glass-Filled Nylon like

Thermoplastic Polyurethane (TPU) like

Fire-Retardant (FR) PU like (78D, 80D, 85D)

High Impact (85D, 88D, 80D – 90D)

Polyamide (PA) like (80D) and more

Customized Surface Treatment

The surface treatment process of vacuum casting parts is mainly to improve the appearance, surface quality, wear resistance, corrosion resistance or other functional requirements. Some common surface treatment processes are listed below: